Research Facilities - APC Project (EHF)

Main menu:

Research Facilities

3D optical measurement system

This optical measurement system is a powerful optical system for measurement of complex materials and structures for their 3D deformation and strain during loading. This tool is a highly robust, full-

The object under load is viewed by one (2D) or two (3D) high-

Forming Measurement Tools Innovations (FMTI)

The FMTI grid analysis system performs strain measurement based on the digitization of the grid image projected onto the flat surface of the CCD sensor of a digital camera. Position of the camera, distance of the lens to the grided surface and the curvature of the grided surface affect the shape and magnification of the image.

Paxcam Digital Microscope Camera

PAXcam is a feature-

aMetallography Equipment

Metallography is the study of a materials microstructure. Analysis of a material's metallographic microstructure aids in determining if the material has been processed correctly and is therefore a critical step for determining product reliability and/or for determining why a material failed. The basic steps for proper metallographic specimen preparation include: documentation, sectioning, mounting, rough grinding, fine grinding, polishing, etching and examination.

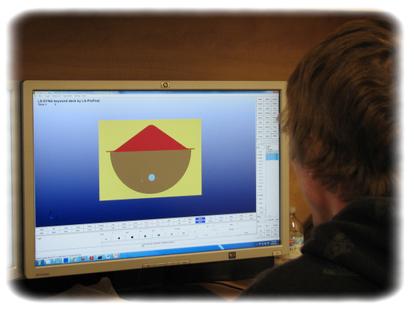

LS-

LS-

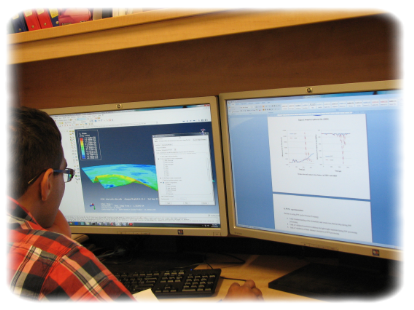

ABAQUS Simulation Software

Abaqus is a suite of software applications for finite element analysis and computer-

SIMULIA Abaqus 6.12 is a powerful and complete solution for performing virtual tests with realistic simulation which helps reduce product development time and costs, while improving reliability. The new release of Abaqus 6.12 provides new features and enhancements for multiphysics, modeling & meshing, and performance.