Investigation of Automotive Fuel Tank Filling and

Venting

This research was conducted in

collaboration with Kautex Textron through an Natural Sciences

and Engineering (NSERC) Collaborative Research and Development (CRD) Grant. It

involved a study of the automotive fuel tank filling process to predict the

complicated two-phase liquid fuel and vent flow rates as well as tank dome

pressure. Of particular interest was the prediction of the occurrence of premature shut-off

and spill-back. An experimental investigation on an instrumented, clear fuel

tank, using gasoline of various grades of volatility and flow rate, formed the

basis of the M.A.Sc. thesis of Maurizio Mastroianni.

A simplified, lumped-parameter model of the entire tank filling process was

developed by Shelagh Fackrell as her M.A.Sc.

thesis. The model included the effects

of vapour generation, fuel volatility, compressibility of the vapour vent flows , fuel dispensing flow rate and venting conditions. It

was capable of predicting the occurrence of premature

shut-off for the experiments to which it was compared and fair agreement with

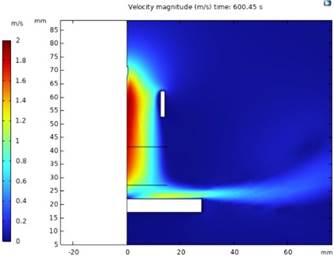

the predicted pressures. A more accurate numerical model of the tank filling

process has been developed by Allan Zhao, a Ph.D. student who successfully

defended his Ph.D. dissertation in December 2002. A combination of a computational fluid

dynamic (CFD) model of the complicated two-phase flow in the filler tube with

lumped parameter models of the vent tube flows and tank vapour and liquid was utilized. This combination is shown to result in a

reduction in computational time compared to the CFD solution. This work has

resulted in a better understanding of the complicated fuel tank filling process

and a practical tool for fuel tank designers.