16

view . fall 2011

It was the start of a new era for

engineering at UWindsor

as the first

occupants of the $112-million Centre for

Engineering Innovation (CEI) began their

move into Phase I of the building in July.

More than 60 laboratories, work centres,

meeting rooms and teaching spaces are

located in Phase I, which also includes the

industrial courtyard and crane bay.

Among the dozens of laboratories and

workspaces that have relocated in Phase I

is the Intelligent Manufacturing Systems

Centre of Research Excellence. The IMS

Centre is the first of its kind in North

America and allows students to design

products, configure the manufacturing

systems to make them, and provides

unique opportunities to experiment with

the entire chain of innovation, says

Dr. Hoda ElMaraghy, Canada Research

Chair in Design and Manufacturing.

“It’s a factory in a lab,” says ElMaraghy,

an engineering professor and director of the

IMS Centre. “It allows us to not only make

things within that factory but to reconfigure

its layout. So, if the market needs change in

six months, we can reconfigure the whole

layout in one hour.”

Opportunities for collaborative

partnerships with industry and research

to benefit the community are a driving

force behind the CEI. Nowhere is this

more evident than in the Wireless

Communications and Information

Processing Lab (WiCIP) now located there.

Dr. Narayan Kar, a Canada Research Chair

and professor of electrical and computer

engineering, received a grant from the Essex

Power Corporation to develop a wireless

fault detection system for electrical power

distribution lines. He is working with

Dr. Kemal Tepe, who specializes in wireless

communications, to develop a device that,

when attached to power lines, identifies

faults when and where they occur and

wirelessly transmits that information to the

power corporation.

“It cannot prevent a fault from

happening but it would speed up the repair

process so that it would lessen the amount

of time people would have to remain in the

dark,” Dr. Kar says.

Kar’s Centre for Hybrid Automotive

Research & Green Energy (CHARGE) is a

state-of-the-art lab also housed in the CEI’s

Phase I. It focuses on the development of

an improved electric drive train system for

electric and hybrid vehicles. Work in the

CHARGE lab will increase the capability,

energy efficiency and performance of the

electric motor, reducing carbon emissions

and dependence on fossil fuels.

Keeping the automotive industry

internationally competitive and ecologically

responsible is the goal of Dr. Daniel Green,

Canada Research Chair in Development &

Optimization of Metal Forming Processes.

Green’s research program will cover the full

spectrum of metal forming manufacturing

processes, from theoretical research to

use in industry. His focus is on the use of

lightweight materials in automotive parts

manufacturing, with expected benefits for

the aerospace and appliance industries

as well. Green says that the manufacture

and use of lightweight materials will

reduce vehicle mass and contribute to the

reduction of greenhouse gas emissions, with

far-reaching economic and environmental

implications.

Construction on the CEI building will

continue through the next several months.

Completion of Phase II is scheduled for

Summer 2012.

CENTRE FOR ENGINEERING:

PHASE ONE MOVE-IN DAY ARRIVES

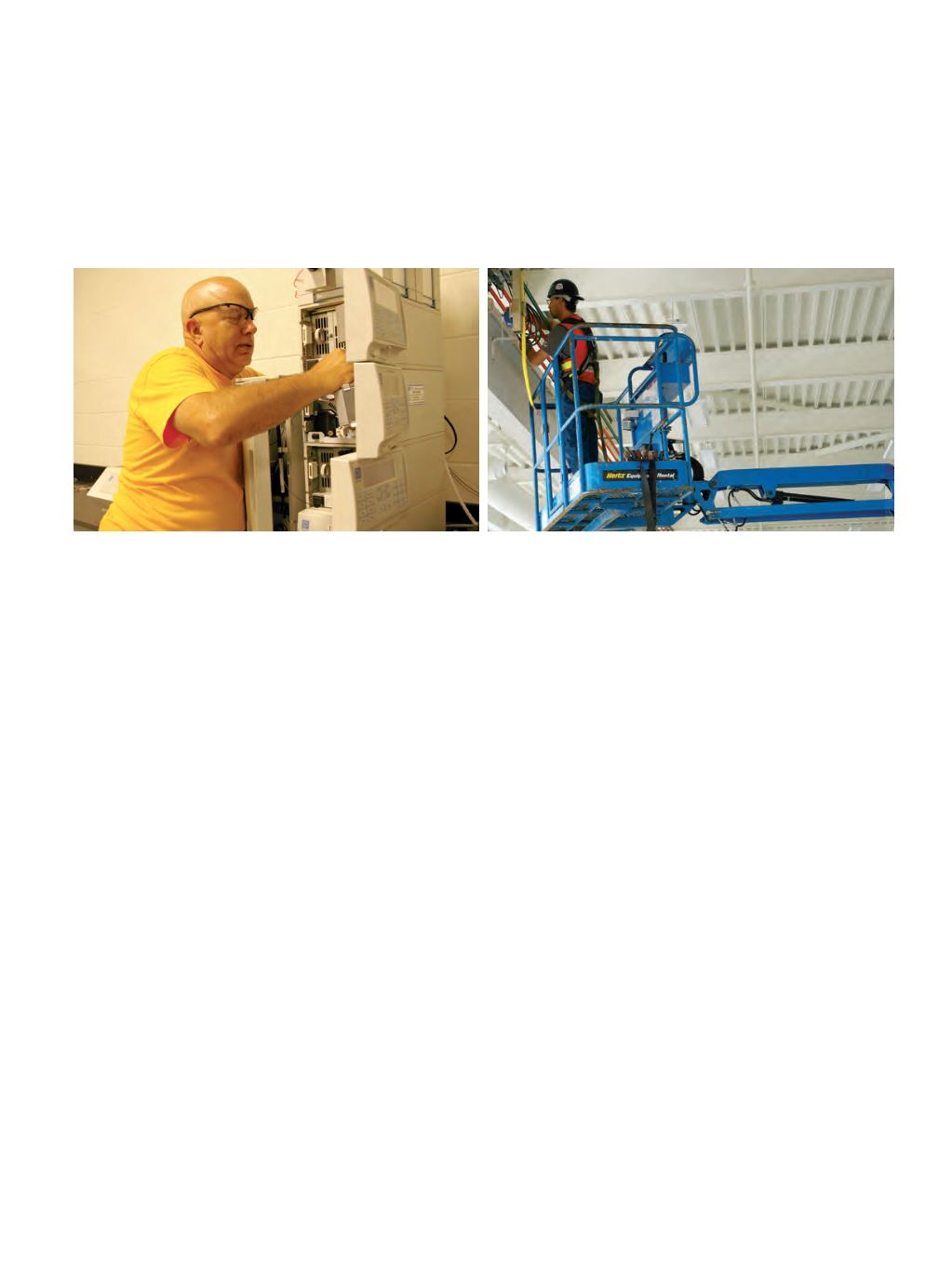

Lab technician Bill Middleton installs air monitoring equipment in one of

the new environmental engineering labs in the first phase of the Centre for

Engineering Innovation.

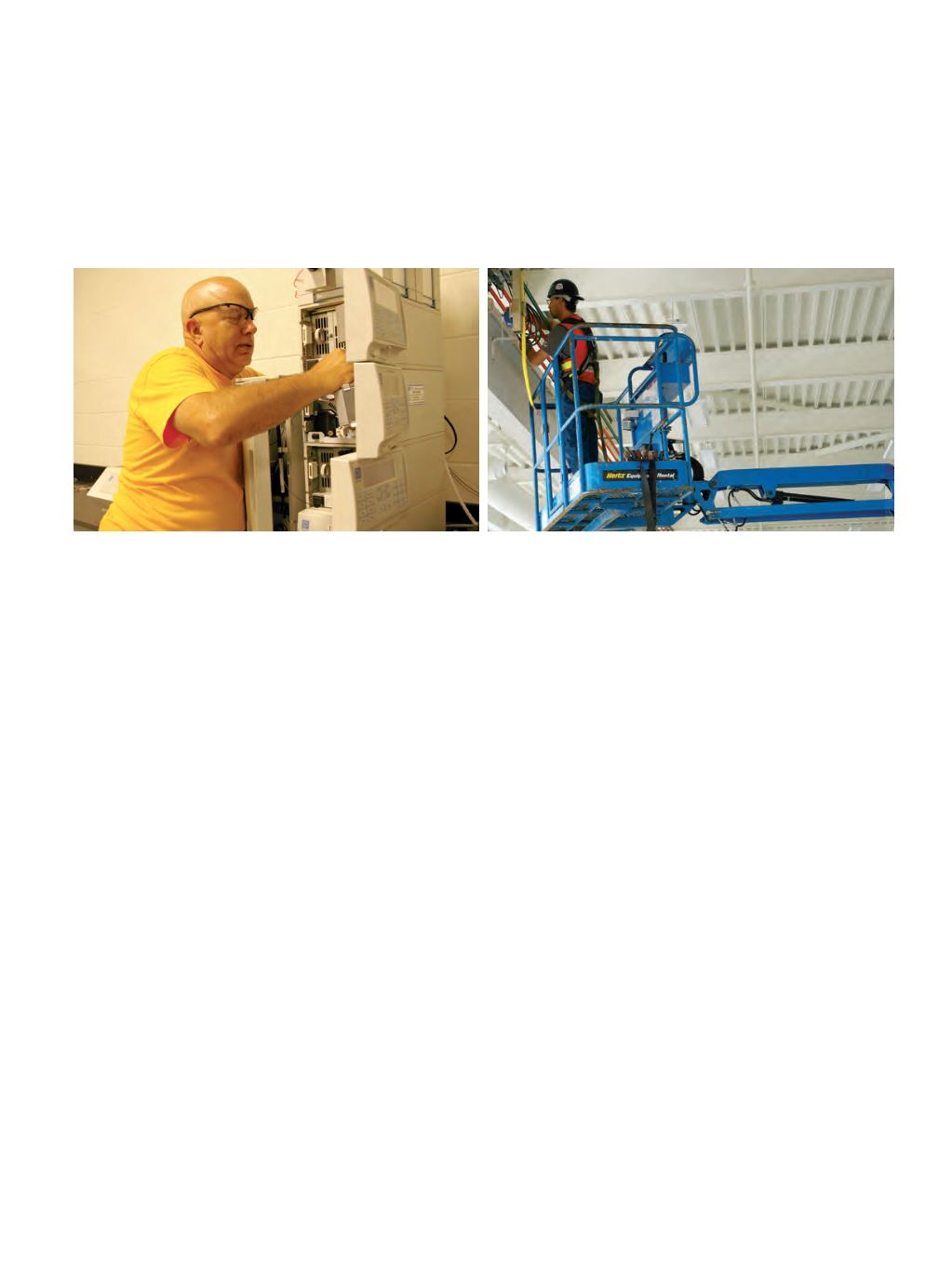

Steve Cicilino, a technician with Kone Cranes, installs power lines for

a crane that will be used in the industrial courtyard in the Centre for

Engineering Innovation.

BY LORI LEWIS